In a world grappling with rapid urbanization, the intense impacts of climate change, and a dire need for sustainable, resilient, and affordable infrastructure, generative design emerges as a beacon of hope. The introduction of generative design into the architecture, engineering, and construction landscape is ushering in a new era of efficiency & sustainability for ‘leveling up’ our built environment.

This report offers an exploration of how algorithm driven, automated, and outcome-based design methodologies are poised to redefine our built world; and specifically, critical infrastructure: transportation systems, water and energy assets, housing, and more. Utilities, engineering firms, technology providers, and investors – join us in uncovering how critical infrastructure projects are being transformed through this State of the Industry Report on Generative Design for Critical Infrastructure.

“Almost without noticing, we have entered an era where the fundamental question is not “What can be done” but “What should be done.

Truly, this is the golden age of engineering.

But even more, it is a golden age for the individual engineer. Driven by technology, design is not dominated by the all-encompassing government design bureaus many imagined in the 1930’s, nor by an oligopoly of giant companies as many saw in the 1960’s. Instead, the basic tools to invent, design, and manufacture have become so inexpensive and widespread that “downsizing” has become at least as much an imperative in management as in design.

We are entering the age where we are limited primarily by our creativity. Our ability to imagine, and the courage to make our dreams into reality will be our most precious resource. In this age, the designer has a resource that most designers of the past could hardly imagine—the computer. Engineers who, less than twenty years ago, toiled into the night with log tables, slide rule, and pencils, making parts, then breaking them on testing machines, or designing circuits and struggling to get them to work can now design on their desktops with productivity hundreds to thousands of times greater. And the products of their minds in turn accelerate the process.

Autodesk Co-Founder

May 16, 1949 – Feb. 2, 2024

It is imperative that responsible parties, including utilities, developers, engineering consultants, and others stay informed of emerging trends and applications of generative design. This report is a compilation of data & insights from leading players of how generative design is revolutionizing project planning, design, and execution within water, power, housing, transportation, and other critical infrastructure sectors.

This is second golden age of engineering. An age where software can help design a sustainable, resilient future throughout the full lifecycle of critical infrastructure projects.

Read on to learn about the forcing factors at play that are rapidly changing the way those responsible for designing, building, and operating our built world are being forced to adopt to new realities.

Total construction spending stood at US $1.98 trillion in August 2023, a 7.4% increase since the previous year. This total spending was primarily driven by nonresidential construction spending (the majority of which is critical infrastructure), which recorded growth at a 17.6% year-over-year increase in August 2023.

And this doesn’t include the backlog of projects that already exist. As of August 2023, backlogs in the nonresidential segment had increased to 9.2 months and are expected to sustain the segment going into next year.

Engineering talent is in short supply, with a growing gap between supply and demand that puts the progress of important industries at risk and threatens to have a tremendous negative impact on the economy—equal to nearly 40% of the projected GDP impact of all talent gaps expected in the US through 2030.

A BCG analysis of Bureau of Labor Statistics (BLS) data indicates that demand for engineering skills will grow by about 13% from 2023 to 2031.

The Japanese Ministry of Economy has predicted a deficit of over 700,000 engineers in Japan by 2030, and the German Economic Institute reported a shortage of 320,000 STEM specialists in Germany as of April 2022.

There is a 133,000 person engineer gap in the U.S. today, where 33% of roles go unfulfilled, and a projected 186,000 engineering job vacancies by 2031.

“Everywhere in the world right now [there] is the need for more talent, better talent,” says Martin Fischer, professor of civil and environmental engineering at Stanford University. Fischer has observed an “expectation of the younger generation to not do stupid work that could be automated. They don’t tolerate it. They just leave.”

The IEA has set a Net Zero Emissions by 2050 Scenario, which requires all new buildings and 20% of existing structures to be zero-carbon-ready by 2030.

According to the US Green Building Council’s 2023 report, sustainability is a top priority for most surveyed Engineering & Construction (E&C) firms, as it aligns with their organizational mission and business strategies.

Whereas nonadopters [of artificial intelligence] “might experience around a 20% decline in their cash flow from today’s levels,”

“With integrated digital technologies, our project managers can objectively assess project status, productivity, and any risks, and [can] make data-based decisions more quickly to improve safety, performance, and outcomes,” says Francesco Tizzani, group manager of digital construction at Leighton Asia, an international construction contractor headquartered in Hong Kong and part of CIMIC Group. “The technologies also reduce manual reporting, enabling our people to focus on analyzing intelligent data to improve project delivery.”

The way we’ve designed our infrastructure in the past is not going to succeed in this new era. There’s too much work to be done, not enough talent to do it, and too many new requirements to effectively and affordably build the infrastructure of the future we need.

As you read on, our objective is to educate interested parties on how critical infrastructure projects are, and will be, transformed with generative design technologies. We will focus on real world applications of generative design in real infrastructure projects around the world, as well as key success metrics for organizations adopting generative design as part of their workflows.

But before we get there, we’d like to propose one other objective: a new success metric by which all relevant industry players should measure themselves by…

This makes sustainability paramount – not only to reduce environmental impact but also to ensure resilience, adaptability, and cost-efficiency over decades.

For too long we’ve focused on measuring the success of projects after the asset is built. Were we within budget? How long did the project take? Does this meet the needs of our communities, now and into the future?

In other words, we are reactively measuring our success. We track the intimate details of lagging success indicators like the total cost to operate and every iota of carbon produced, but fail to proactively address these concerns during the planning phases of projects.

We need to shift to proactive measurements of success. And one measure, in particular, stands head and shoulders above the rest…

For purposes of this report, we are comparing generative design and AI-powered design methodologies to manual design in critical infrastructure projects.

Generative design, on the other hand, is an iterative design process that involves the use of algorithms and computational techniques to generate a broad spectrum of design options, typically optimized for specific predefined criteria.

Artificial intelligence is often used to power generative design software and the design generation & options assessments that come with use of these programs.

Critical infrastructure refers to the physical assets that society relies upon for everyday functioning and overall well-being. For context of this report, we focus on critical infrastructure in the built environment. The next slide outlines the exact asset types we’re referring to.

SEPTEMBER 12. 2022

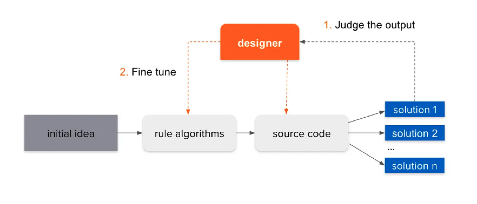

Generative design harnesses the power of artificial intelligence (AI) to generate design iterations based on constraints identified by the designer or engineer. Generative design uses AI to some extent, but it is just one step in the process. Humans are required at the beginning of the process to define constraints and at the end of the process as the final decision-maker. After all, someone needs to sift through the list of design iterations generative design creates!

Depending on the definition, generative design can be traced back to Gerald L. Delon’s 1970 paper A Methodology for Total Hospital Design.

As CAD software began to proliferate throughout the 1980’s and 1990’s, programmers began applying generative design to component level design – and continue to do so today. Generative design aids engineers in creating new options like individual parts of a car, variations of a type of sneaker, and unique architectural arrangements.

But only recently has generative design hit the ‘mainstream’ in critical infrastructure projects – and even then, many industries are not yet served by a specific company or solution.

This section of the report provides a (non-exhaustive) list of generative design companies solving challenges in specific industry verticals, as well as the project phases they are best applied in.

Generative design software can be applied during various phases of critical infrastructure projects.

Generally, we find generative design software most applied in the planning & conceptual design phases of projects; however, there are uses cases throughout detailed design and construction.

The ‘Cheat Sheet’ on the next slide provides a nice overview of some of the companies and the phases of projects they support – while not all are generative design (some are purely AI or generative AI) – it paints a nice sample of examples throughout project lifecycles.

Special credit to Stjepan Mikulic of the AI in AEC Hub for creating the initial version of this one

Despite its emerging importance in critical infrastructure, generative design is already making real impacts in projects around the world.

In this section, we break down case studies by critical infrastructure vertical – showcasing the tangible impacts of generative design on project workflows and project outcomes achieved.

We then end the section with a call to action for Utility and AEC/EPC companies interested in adopting these technologies, recommending KPI’s by which they can measure the success of the use of generative design within their organizations.

“The Bipartisan Infrastructure Law will make a once-in-a-generation investment of $350 billion in highway programs through 2026. This includes the largest dedicated bridge investment since the construction of the interstate highway system 67 years ago.

The need for new infrastructure is urgent, with 1 in 5 miles of highways and major roads, and 45,000 bridges in the US alone in poor condition. State DOTs and the industry have more reasons than ever to transform the way transportation infrastructure projects are designed, built, operated, and maintained.”

VP, AEC Design & Engineering Strategy

Autodesk

Three major European general contractors – Skanska, Costain, and STRABAG – formed a joint venture, SCs JV, to optimize the construction of the London tunnels of HS2, a national high-speed railway linking London, Birmingham and the north of the country. The HS2 network will ultimately carry more than 30 million travelers each year. SCS JV is constructing 13 miles of twin-bore tunnels on the HS2 route, terminating at Euston station in central London. The company has divided its tunnels work into three areas – west, central, and east – and in its initial work with ALICE, SCS JV has focused on the east area, where HS emerges from the tunnels on its final 0.6-mile route to Euston station.

In its first work with ALICE, the question at hand for SCS JV was: could it use ALICE to find efficient sequencing options to enable an earlier construction start for the Euston cavern shaft, which provides critical access to the main tunnels that lead to Euston station.

Through “what-if” analysis with ALICE, the SCS JV team was able to identify several ways to re-sequence and improve the build time for the pre-shaft sinking activities. Changing when they would construct the spoil conveyor, which would remove soil from the excavation and work area, was one such important influencer of the schedule.

SCS JV also determined that they could save time and improve efficiency by having concurrent workforce teams constructing activities to the cavern headhouse base slab, and key milestones, which would enable construction of the cavern shaft earlier than planned.

With the ALICE platform, the SCS JV team was able to trim the build time for the shaft by 86 working days, a savings worth E2M in associated overhead expenses.

“Construction optioneering with ALICE has enabled us to quickly and effectively explore alternative ways to build,” said Andy Irwin, SCL Agent at SCS JV. “The savings of both time and money that we’ve identified with this initial work on SCS East has been significant, and we’re now looking forward to expanding our use of ALICE to other portions of the project.*

Montgomery County’s Department of Transportation was using a mix of generic and traditional tools to complete conceptual street design alternatives. This process was cumbersome, siloed, and slower than the pace they were striving for. They needed an all-in-one tool that could allow the County to deliver quickly on the early phase work for their community.

The County introduced new conceptual street design technology, powered by Remix, that enabled them to save money and staff time, accelerate project timelines, and gain valuable process efficiencies, all leading to better outcomes for the County.

Accelerated project kickoff timeline by 4-6 weeks

“When it comes to the design of next-gen power systems, the technologies that will be most useful will be those that operate (or empower engineers to operate) across domains and disciplines. AI and ML are increasingly seen as being at the nexus between data, describing what is or what has been, design objectives (or the desired future state), and design constraints (or best practices). This nexus is where the magic is happening in the industry right now.”

Energy Transcend

Designing solar power plants is a detailed and intricate process. Traditional methods can be slow and susceptible to mistakes, particularly as the scale and complexity of the projects increase. Large-scale projects, involving extensive layouts with roads and transformer station locations, require precision and efficiency to avoid costly errors and delays. The company faced challenges in managing these complexities efficiently while maintaining high standards of accuracy and speed in their design processes.

In its first work with ALICE, the question at hand for SCS JV was: could it use ALICE to find efficient sequencing options to enable an earlier construction start for the Euston cavern shaft, which provides critical access to the main tunnels that lead to Euston station.

The company adopted PVcase Ground Mount software to address these challenges.

PVcase stands out for its seamless integration with widely-used engineering software like AutoCAD, enhancing its utility and flexibility. Its user-friendly interface and powerful features streamline the entire design process, from basic to detailed engineering, and support execution engineering. The software enables quick development of project layouts, reducing the time spent on design phases significantly. One of the key advantages of PVcase is its capability to minimize human errors early in the design process, thus ensuring a higher level of accuracy in the final layouts.

The introduction of PVcase Ground Mount software had a transformative impact on the lberica Solar’s operations. The time savings realized with PVcase were substantial, especially in the initial phases of project development, where more than 50% time reduction was observed.

This efficiency gain was even more critical in the context of very large solar plants, where the complexity and number of variables increase exponentially. The ability to generate several layouts for the same project within a single day allowed the company to offer more options to their clients, enhancing customer satisfaction.

For a practical example, a project that previously took three days to layout could now be completed in just one day with PVcase, including multiple versions of the layout without any compromise on accuracy. Additionally, the software’s topographical 3D cabling features provided precise cable length estimates for both level 1 and level 2 of plant design, facilitating more accurate budgeting and planning.

“Unprecedented demand for digital infrastructure is driving technological innovation. Customers are seeking to optimize efficiency and flexibility in a tight market, and that’s increasingly pushing providers to develop new solutions and approaches. This includes everything from leveraging alternate power sources for added reliability to embracing the technological and infrastructure changes needed to accommodate AI.”

CEO and Board Member Aligned Data Centers

The effectiveness of a cooling system depends on airflow distribution to provide uniform IT inlet temperature without hotspots in any of the data center server halls. Larsen & Toubro needed a tool to help design a data center cooling system that would be effective for different modes of operation. They needed to do a detailed analysis of airflow and transfer in data center design, conduct “what if” scenarios to check design effectiveness, and get insight into data center performance Issues.

To minimize rework and risk of failure, Larsen & Toubro turned to the Cadence DataCenter Design Software. They found it useful for simulation and analysis of the cooling system to gain insight into the design and to make the necessary changes to meet the performance requirements.

The variety of CFD results from the DataCenter Design Software helped them visualize and evaluate performance characteristics such as temperature, velocity, and pressure, as well as identify opportunities to improve design modifications.

“With rising housing needs and land shortages, getting more out of the buildings that we build is of primary concern. Generative Design enables each individual designer to optimize—giving us more in a world of scarcity.“

Senior VP, Growth TestFit

On average RBA spent about 20-30 hours in AutoCAD to create a site plan for a project including:

sktich intu cient approvals

On top of that, they would need to then model the 3D massing in Revit for an additional 30-40 hours.

RBA was looking for a tool that could check off all their requirements: The team kept coming back to TestFit during the evaluation process not only because it met all the core criteria, but also because it offered the customization that RBA needed. From the very beginning, RBA was able to import its configuration and standards into TestFit without compromising its existing unit standards-a feature that other platforms couldn’t offer in their evaluation.

With TestFit’s real-time Al configurators, RBA were able to get their work done 10x faster – 4-6 hours – and see the design from 2D to 3D instantly.

Epcon Communities has won numerous awards for its floor plans and kitchen layouts, but it had been years since they overhauled the curb appeal of their home designs. But in 2022, after participating in the Parade of Homes near their headquarters in Columbus, Ohio, their leadership decided it was time for a chang.

Epcon wanted to level up their exterior, make it more contemporary and at the same time, make some updates to the interior layouts of our homes.

Unlike other rendering services, Highare creates high-quality 3D renderings directly from the model in the system, eliminating errors and drastically increasing the speed at which renderings can be produced. Renderings are ready in 2-3 days instead of weeks, allowing the Epcon Team a visual crosscheck of the changes they had made in design. The result? Peace of mind that they were on the right track.

Higharc’s ability to render a large number of home variations quickly and accurately allowed Epcon to drastically increase the number of renderings they ordered, providing more transparency in the design process and more visual decision-making support tools for their customers.

“In the past, because it was so labor intensive and expensive, we would select only a handful of elevations to render within the unit type, and we typically wouldn’t do secondary or community-specific color palettes in renderings,” said Mats Alstrom, Epcon’s Director of Design. “But since it’s so quick to do and so cost effectin wei g in the perise providing our salespeople with many more

“Infrastructure worldwide is evolving with digital and physical tools making a big impact. For instance, the UK water industry has committed to becoming carbon neutral by 2030, unlike the U.S. with its 50,000 utilities lacking similar mandates. The future of critical infrastructure involves using generative design to thoroughly assess project impacts. The key opportunity is to design resilient infrastructure now, rather than dealing with problems later.”

Co-Founder Transcend

Rayerbazar WWTP is a new plant being planned by Dhaka WASA & proposed for ADB funding. The biggest risk factors for this project were the cost and time related to land constraints and acquisition. Dhaka is a dense city and it was imperative that the footprint of this WWTP be minimized as much as possible.

ADB partnered with Transcend to pilot its generative design software to streamline project planning and design for the Rayerbazar WWTP. •Transcend Design Generator TDG) enabled ADB and Dhaka WASA to generate 10+ concept design options, compared to 2-3 options typically evaluated for a project.

Compact WWTP site-specific options included features like deeper reaction tanks, rectangular vs. circular clarifiers, and a phased facility build-out.

Reduced risk with 5x more options

ADB and Dhaka WASA used TDG to minimize the project’s risk by generating 5x more design options with lower physical footprint, translating to significant cost-savings

More detail, better insights

TDG’s automated engineering documents, including a 3D BIM model, informed ADB and Dhaka WASA with details for project planning and future construction bidding. This level of detail was not previously available for concept designs

Faster Decisions: 8 Months to 8 Weeks

TDG produced outputs within hours significantly speeding up the decision-making process. Decisions that typically take 8-10 months can now be accomplished within 8-12 weeks using generative design software.

“If you think of the city as a platform, and design in the ability for people to change it as quickly as you and I can customize our iPhones, you make it authentic because it doesn’t just reflect a central plan.”

NY Department of Environmental Protection

Intep approached Urbio to overcome 3 challenges:

Inefficient process for gathering accurate data over a perimeter

Tedious combination of spreadsheets and GIS tools

Inadequate macro analysis made it hard to deliver actionable solutions to quickly implement

Structure the data

Relying on Urbio’s curated data and on the municipality’s own data, the energy engineer quickly set up an accurate digital twin of the building stock characterized by dozens of criteria.

Visualize the current state

Once the Digital Twin was built, the engineer selected the most relevant criteria to illustrate the municipality’s current state.

The instant creation of customized maps contextualized the analyzes and served as figures for the discussions with the stakeholders.

Identify the key levers

The engineer applied its custom filters and summary templates to quantify the impact of specific measures on the municipalities objectives.

Based on these metrics, the city was able to take strategic decisions such as targeting the most impactful buildings for retrofit measures or renewable electricity production.

Miller Electric Company is an American electrical engineering firm established in 1928 with an annual revenue of around $600M, 19 office locations, and more than a thousand employees. Miller Electric Company faces typical but urgent industry challenges associated with designing electrical raceway systems for large-scale commercial buildings:

They are eager to find ways to make their design teams more efficient, using new processes and technologies.

Miller Electric Company undertook a pilot project led by Adam S. Davis, Sr. Manager, Fabrication & Modularization, to partner with Augmenta. Using Augmenta’s automated Electrical Design Module, they completely automated the process of designing electrical raceway systems. Running Augmenta’s software on historical projects, Miller Electric Company compared the solutions generated and the time to create those designs with the output of their traditional design processes. They retroactively automated the design of electrical conduit for two medical facilities.

Augmenta enabled Miller Electric Company to significantly increase the capacity of their VDC team. They realized around 40% time-savings in electrical modeling time across their Augmenta pilot projects – the equivalent of adding 2-3 BIM team member’s time, without adding more overhead costs. Furthermore, they predict that with time-savings and the Augmenta platform’s capability to estimate material and labor costs, their VDC team will be able to provide detailed estimates both during bidding and when responding to change requests. Ultimately, Augmenta will enable Miller Electric Company’s VDC team to maintain a competitive edge in the evolving construction sector.

PR - how your firm talks about generative design

Projects & Profit - how your firm recoups ROI with generative design software

People - how you attract, train, and retain individuals that utilize generative design

How often does your marketing (website, advertisements, collateral, etc.) emphasize generative design as part of the value your organization brings to your customer?

How often are you mentioned in news outlets, social, etc. (Share of Voice) for topics related to generative design?

How often are leaders sharing topics related to generative design, both inside and outside of the company?

Is generative design listed as a strategic priority on your organizational communication roadmap?

Do you showcase case studies around outcomes created for customers by utilizing generative design tools?

% of applicable employees familiar with the concept of generative design

% of applicable job descriptions mentioning generative design or requiring experience in building and/or utilizing generative design tools

% of applicable employees using generative design software on critical infrastructure projects

% increase in job satisfaction for employees using generative design tools

The use of generative design in critical infrastructure projects represents a transformative approach in how we plan, design, and optimize infrastructure projects in the second golden age of engineering.

By leveraging generative design tools, the world’s designers can effectively address the most complex infrastructure challenges; leading to substantial cost savings, streamlined project planning phases, and ultimately the reshaping of entire urban landscapes…

Creating sustainable, adaptable, inclusive, and resilient cities of the future.